The Eco-Luxe Revolution: How Bamboo Fabric is Transforming UK Sustainable Fashion

Bamboo fabric has gained attention as a textile that blends comfort with environmental consciousness. Bamboo-based textiles are semi-synthetic materials created from bamboo plants through chemical or mechanical processing, offering properties similar to silk but with enhanced breathability and moisture-wicking capabilities.

This versatile material shows up in everything from t-shirts to bed linens, earning praise for its soft texture and natural antimicrobial qualities. Sustainable bamboo fabrics come in several forms, including viscose rayon and lyocell, each with unique characteristics suited for different uses.

The popularity of bamboo textiles stems from growing interest in eco-friendly alternatives to traditional fabrics. While the bamboo plant grows quickly with minimal resources, the manufacturing process varies in its environmental impact depending on the production method chosen.

On This Page

Key Takeaways

- Bamboo fabric offers silk-like softness with superior moisture management and antimicrobial properties

- The manufacturing process transforms bamboo from plant to textile through either chemical or mechanical methods

- Different types of bamboo fabrics suit various purposes, from clothing to home textiles

The Bamboo Plant and Fabric Origination

Bamboo plants grow rapidly and transform into soft, durable textiles through modern processing methods. The plant’s natural properties make it an excellent choice for sustainable fabric production.

Understanding Bamboo as a Renewable Resource

Bamboo grows at an astonishing rate of up to 91 centimetres per day. The fast-growing plant needs no pesticides and regenerates from its own roots, making it highly sustainable.

Unlike cotton, bamboo requires minimal water to thrive. A single bamboo plant can be harvested multiple times, with new shoots emerging from the existing root system.

Key sustainability features:

- Self-regenerating root system

- Minimal water requirements

- No need for chemical pesticides

- Annual harvest capability

- Natural pest resistance

The Transition from Bamboo to Fibre

The process of creating bamboo fabric starts with crushing the woody parts of the plant. Workers extract the bamboo fibres through either mechanical or chemical processes.

The mechanical method involves crushing and natural enzymes to break down the bamboo walls. This creates a mushy mass that machines spin into yarn.

Chemical processing uses sodium hydroxide and carbon disulfide to dissolve the bamboo into a pulp. This solution passes through spinnerets to form threads, which then become yarn for weaving.

History of Bamboo Fabric in the UK

Bamboo textiles have a relatively short but impactful history in the UK market. Initially introduced in the early 2000s as a novelty sustainable material, bamboo fabric gained significant momentum around 2010 when UK consumers began prioritising eco-friendly alternatives to traditional textiles.

The 2010s marked a turning point, with UK retailers like Marks & Spencer and John Lewis introducing bamboo-based bedding and clothing lines. By 2015, specialised UK bamboo clothing brands began to emerge, catering to growing consumer interest in sustainable fashion.

The COVID-19 pandemic further accelerated bamboo fabric adoption in the UK, with increased demand for comfortable loungewear and antimicrobial textiles. Recent years have seen bamboo firmly establish itself within the UK sustainable fashion landscape, with year-on-year growth consistently exceeding 15% since 2020.

Key milestones in UK bamboo fabric history:

- 2005: First bamboo textile products appear in UK speciality shops

- 2010: Major UK retailers begin stocking bamboo bed linens

- 2015: Launch of first UK-based dedicated bamboo clothing brands

- 2018: UK Trading Standards introduces stricter labelling requirements for bamboo textiles

- 2021: UK bamboo textile market exceeds £45 million in annual sales

- 2023: Bamboo becomes the fastest-growing sustainable fabric category in UK fashion retail

Bamboo Fabric Production Process

Bamboo transforms into textile fibres through distinct manufacturing methods that vary in their environmental impact and end product characteristics. The specific processing technique directly affects the fabric’s quality and sustainability.

Mechanical Versus Chemical Processing

Mechanical processing of bamboo creates natural fibres by crushing the plant material and using natural enzymes to break down cell walls. This method yields a coarser textile suitable for sturdy fabrics.

Chemical processing dominates commercial production. It uses strong solvents to dissolve bamboo into a pulp. This method creates finer, softer fabrics but raises environmental concerns.

Most bamboo textile production occurs in China, where manufacturers often favour chemical methods for their cost-effectiveness and higher output rates.

Traditional Viscose Rayon Compared to Bamboo Viscose

Bamboo viscose production mirrors traditional viscose rayon manufacturing. Both processes use sodium hydroxide and carbon disulphide to break down cellulose.

The key difference lies in the raw material. Traditional viscose uses wood pulp, whilst bamboo viscose starts with bamboo cellulose.

The chemical transformation makes bamboo viscose chemically identical to regular viscose rayon, despite marketing claims suggesting otherwise.

Creating Sustainable Bamboo Lyocell

Bamboo lyocell represents a more eco-friendly alternative. The process uses a closed-loop system where 99% of chemicals are recovered and reused.

The non-toxic solvent N-Methylmorpholine N-oxide (NMMO) breaks down bamboo cellulose. This creates minimal chemical waste and produces strong, durable fibres.

The manufacturing process requires specialised facilities and higher production costs, but yields a truly sustainable textile with excellent moisture-wicking properties.

UK Regulatory Framework for Bamboo Textiles

The UK regulatory landscape for bamboo textiles has evolved significantly, especially after Brexit introduced new requirements for textile importation. According to UK Trading Standards, products labelled simply as “bamboo” must contain 100% mechanically processed bamboo fibres. Products made through chemical processing must be labelled as “viscose from bamboo” or “lyocell from bamboo” to avoid misleading consumers.

The Competition and Markets Authority (CMA) has also introduced Green Claims Code guidelines affecting bamboo textile marketing in the UK. These regulations prohibit vague environmental claims and require specific evidence for sustainability assertions.

Post-Brexit, the UK Conformity Assessed (UKCA) marking now applies to certain bamboo textile products, replacing the previous CE marking. Importers of bamboo textiles to the UK must ensure compliance with:

- UK Registration, Evaluation, Authorisation and Restriction of Chemicals (UK REACH)

- General Product Safety Regulations 2005

- Textile Products (Labelling and Fibre Composition) Regulations 2012 (as amended)

Non-compliance can result in significant penalties, including fines of up to £5,000 per offence and potential product recalls.

Types of Bamboo Fabrics and Textiles

Bamboo can be transformed into several distinct textile types through different manufacturing processes. Each type offers unique properties and characteristics that make them suitable for various applications in clothing and home textiles.

Comparing Bamboo Viscose, Rayon and Lyocell

Bamboo viscose and rayon are essentially the same material, produced through a chemical process that converts bamboo pulp into fibres. These fabrics are incredibly soft and silky to touch.

Bamboo viscose has excellent draping qualities and feels smooth against the skin. It maintains its shape well after washing and offers strong moisture-wicking properties.

Lyocell bamboo fabrics use a more eco-friendly manufacturing process with non-toxic solvents. The resulting textile is quite durable and maintains its strength when wet.

The Variety of Bamboo Fabrics – From Jersey to Linen

Bamboo jersey is a knitted fabric with natural stretch and excellent draping properties. It’s particularly popular in t-shirts and casual wear.

Bamboo linen uses mechanical processing rather than chemical treatments. While not as soft as viscose, it offers exceptional durability and becomes softer with each wash.

Popular bamboo fabric blends include:

- Bamboo-cotton mixes for enhanced breathability

- Bamboo-spandex for athletic wear

- Bamboo-wool combinations for winter garments

UK Sustainability Certifications for Bamboo Textiles

When shopping for bamboo textiles in the UK, several key certifications verify sustainability claims and ethical production. The Global Organic Textile Standard (GOTS) certifies the entire production process, from harvesting to manufacturing, ensuring environmentally and socially responsible practices.

OEKO-TEX® Standard 100 certification, widely recognized in UK markets, guarantees bamboo textiles are free from harmful substances and safe for human use. This certification is particularly important for bamboo baby clothes and bedding popular among UK consumers.

The UK Soil Association certification applies to bamboo products using organic farming practices, though this primarily covers mechanical processing rather than chemical viscose production.

For sustainably sourced bamboo, UK consumers should look for Forest Stewardship Council (FSC) certification, which ensures the bamboo was harvested from responsibly managed forests.

Cradle to Cradle (C2C) certification, gaining popularity in the UK sustainable fashion sector, verifies bamboo textiles are designed for circular economy principles with minimal waste.

UK retailers increasingly prioritise these certifications, with major department stores like John Lewis and Selfridges requiring at least one sustainability certification for their bamboo textile ranges.

Characteristics of Bamboo Fabric

Bamboo fabric stands out for its remarkable natural properties. The material offers exceptional comfort while maintaining durability and functionality in various conditions.

Softness and Comfort Levels

Bamboo textiles feel incredibly soft against the skin, similar to silk or high-grade cotton. The fibres create a smooth surface that won’t irritate sensitive skin.

The material’s hypoallergenic properties make it ideal for people with skin sensitivities or allergies. Its gentle nature prevents skin irritation and rashes.

Many users compare the texture to cashmere or silk, but at a more affordable price point. The softness remains consistent even after multiple washes.

Durability and Care Instructions

Bamboo fabric maintains its shape and quality with proper care. Machine wash at 30-40°C using mild detergent to preserve the fibres.

Care instructions:

- Wash with similar colours

- Avoid bleach and fabric softeners

- Tumble dry on low heat

- Iron on medium if needed

The material resists pilling better than many traditional fabrics. Regular washing won’t compromise its structural integrity when following proper care guidelines.

Thermal Regulation and Breathability

The natural structure of bamboo fibres creates excellent breathability. Small gaps in the fabric allow air to flow freely, regulating temperature effectively.

In warm weather, the material keeps the wearer cool. During colder months, it provides warmth without overheating.

The thermal regulation makes it perfect for:

- Exercise clothing

- Bedding

- Year-round garments

- Layering pieces

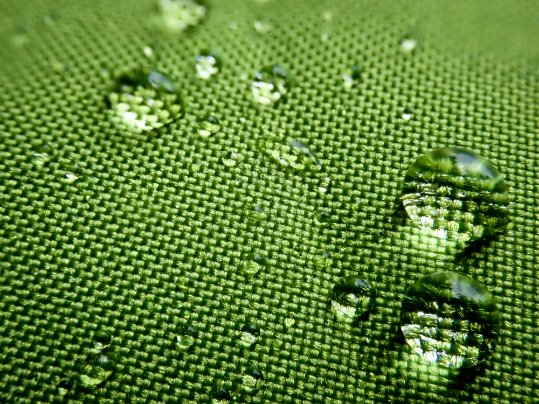

Moisture-Wicking and Antibacterial Properties

Bamboo fabric actively draws moisture away from the skin, keeping the wearer dry and comfortable. This property makes it excellent for activewear and humid climates.

The natural antibacterial qualities of bamboo persist in the fabric form. These properties help:

- Reduce odour

- Prevent bacterial growth

- Keep clothes fresher longer

- Minimise skin issues

The material dries quickly after washing or sweating, making it practical for daily wear and athletic activities.

Health Benefits for UK Consumers

Bamboo fabric offers several health advantages particularly relevant to UK consumers dealing with the country’s unique climate conditions. The UK’s damp and variable weather can exacerbate skin conditions like eczema and psoriasis, which affect approximately 15% of the British population according to the National Eczema Society.

Bamboo’s exceptional breathability and moisture management help reduce skin irritation caused by dampness and overheating, common triggers for flare-ups in the UK’s frequently changing weather. NHS dermatologists increasingly recommend bamboo bedding for patients with sensitive skin conditions.

For the 13 million UK hay fever sufferers, bamboo fabrics provide relief during pollen season. The fabric’s tight weave and natural antimicrobial properties help reduce pollen accumulation compared to cotton or synthetic materials. One UK study found that bamboo pillowcases retained 43% less pollen than traditional cotton alternatives.

During the UK’s cool, damp winters, bamboo’s thermal regulation properties prevent the overheating that often occurs with synthetic thermal wear. This reduces sweat accumulation and subsequent chilling, helping prevent common winter ailments.

UK healthcare professionals particularly recommend bamboo socks for the country’s 4.7 million diabetic patients, as the material’s moisture-wicking and antimicrobial properties help prevent foot complications common in Britain’s damp climate.

Environmental Impact of Bamboo Fabric

Bamboo fabric production has complex effects on the environment. The raw material offers natural benefits, but manufacturing processes can pose challenges to sustainability.

Assessing the Environmental Footprint

Converting bamboo into fabric requires intensive chemical processing that can harm ecosystems. The process uses harsh chemicals like sodium hydroxide and carbon disulfide, which create toxic waste if not properly managed.

Bamboo plants grow quickly without pesticides and need little water compared to cotton. They also release 35% more oxygen into the air than similar-sized trees.

The transportation impact varies based on where the bamboo is grown and processed. Most bamboo fabric production occurs in China, increasing carbon emissions when shipped globally.

Carbon Footprint of Bamboo Textiles in the UK

The carbon footprint of bamboo textiles in the UK market deserves careful consideration. According to the Carbon Trust, bamboo fabrics imported to the UK from China typically generate 1.8kg of CO2 per kg of fabric in shipping emissions alone. This contributes to the total carbon footprint, which ranges from 6.2kg to 9.5kg CO2e per kg of bamboo viscose fabric.

When compared to UK-produced cotton (5.3kg CO2e per kg) and polyester (7.2kg CO2e per kg), bamboo’s carbon impact varies based on processing method. Mechanically processed bamboo has a lower overall carbon footprint at 4.8kg CO2e per kg, while chemical processing increases emissions significantly.

UK initiatives like the Sustainable Clothing Action Plan (SCAP) work to reduce these impacts through improved shipping efficiency and local processing. Companies participating in SCAP have committed to reducing their carbon footprint by 15% by 2030.

Several UK retailers now offer carbon-neutral bamboo products through carbon offset programmes. Brands like BAM Clothing have pioneered carbon labelling on their bamboo garments, allowing UK consumers to make informed decisions.

Biodegradability and Waste Reduction

Pure bamboo fabric breaks down naturally in landfills within a year when processed using the mechanical method. This makes it more eco-friendly than synthetic materials that take decades to decompose.

The material requires less frequent washing than many other fabrics. It naturally resists odours and bacteria, reducing water and energy use over its lifetime.

Many bamboo textile products contain only partial bamboo content. Labels should be checked carefully, as some items marketed as bamboo may include as little as 10% bamboo fibre mixed with synthetic materials.

Leading UK Bamboo Clothing Brands

The UK bamboo textile market has seen remarkable growth, with several British brands at the forefront of innovation. BAM Clothing, founded in 2006 by former pole-vaulter David Gordon, has established itself as a market leader in bamboo activewear. Based in Devon, BAM’s product range includes performance clothing specifically designed for the British climate, with prices ranging from £25 for basic t-shirts to £95 for technical jackets.

Thought Clothing, another UK pioneer, combines bamboo with other sustainable materials to create versatile everyday wear. Their London-designed collections emphasize durability in UK weather conditions, with bamboo jerseys and jumpers priced between £45-85.

Panda London has revolutionized the UK bamboo bedding market with their luxury sheet sets (£80-150) and towels (£15-45). Their products highlight bamboo’s temperature-regulating properties, ideal for the UK’s variable climate.

Boody, while Australian-founded, has gained significant UK market share through their minimalist bamboo basics. Available through major UK retailers including John Lewis, their bamboo underwear (£12-25) and loungewear (£35-65) emphasize comfort and longevity.

Bamboo Clothing UK offers the largest selection of 100% bamboo textiles manufactured to UK standards. Their signature seamless bamboo underwear (£15-30) has developed a loyal following among British consumers with sensitive skin.

Many of these brands have physical presence in British high streets, with Panda London products available at John Lewis, Boody at Selfridges, and BAM Clothing operating pop-up shops in major UK cities.

Use of Bamboo Fabric in Clothing and Textile Products

Bamboo fabric has emerged as a versatile material in modern textiles. Its natural properties make it ideal for a wide range of clothing and home textile applications, from everyday wear to specialised athletic gear.

Bamboo Clothing for Different Styles and Needs

Bamboo clothing adapts well to various fashion styles and practical needs. T-shirts and casual tops made from bamboo offer exceptional softness and breathability.

Bamboo socks have gained popularity for their moisture-wicking properties and natural antibacterial qualities, making them excellent for daily wear.

Many designers now incorporate bamboo fabrics into their collections, creating everything from formal wear to casual attire. The material’s natural drape and lustre make it particularly suitable for flowing dresses and lightweight blouses.

Bedding, Towels, and Homeware Applications

Bamboo bed linens provide a luxuriously soft sleeping experience. The fabric’s natural temperature-regulating properties help maintain comfort throughout the night.

Bamboo towels offer superior absorption compared to traditional cotton versions. They dry quickly and resist bacterial growth, making them ideal for bathrooms and kitchens.

The material’s durability makes it perfect for tablecloths, napkins, and other household textiles that require frequent washing.

Bamboo Activewear and Loungewear

Knitted bamboo fabric creates flexible, stretchable activewear that moves with the body. Its moisture-wicking properties make it ideal for yoga clothes and running gear.

The fabric’s breathability and temperature regulation make it perfect for loungewear. Bamboo pyjamas and robes offer comfort without overheating.

Athletes appreciate bamboo activewear for its ability to reduce odours during intense workouts. The material’s natural UV protection adds another practical benefit for outdoor sports enthusiasts.

UK Consumer Experiences with Bamboo Fabrics

British consumers have developed distinct perspectives on bamboo textiles based on their experiences with the fabric in UK conditions. Sarah Thompson, a yoga instructor from Manchester, notes that her bamboo activewear “performs exceptionally well during hot yoga sessions, maintaining freshness even after intense workouts in ways my previous synthetic gear never could.”

James Wilson, a London-based professional who suffers from eczema, shares that switching to bamboo bedding has “dramatically reduced nighttime flare-ups,” adding that “the fabric feels luxurious while managing the dampness that often triggers my skin condition.”

Catherine Murray from Edinburgh reports that her bamboo clothing “holds up remarkably well to the Scottish weather, providing warmth without overheating during unpredictable temperature changes.”

Consumer research conducted by UK retailer John Lewis found that 83% of bamboo textile purchasers reported satisfaction with their investment, citing durability as a key factor. The average bamboo garment in their study lasted 4.2 years compared to 2.8 years for equivalent cotton items.

In terms of value perception, 68% of UK bamboo textile users surveyed by Retail Week considered the higher price justified by performance and longevity. The survey noted that second purchases of bamboo products were driven primarily by performance rather than environmental concerns.

Weather adaptability emerges as a particular strength in UK consumer feedback. Emma Davis from Wales remarks that her bamboo raincoat “manages moisture brilliantly in our damp climate, preventing that clammy feeling typical with other water-resistant materials.”

Where to Buy Bamboo Fabric in the UK

The UK offers numerous options for purchasing bamboo fabrics and products, with availability spanning from specialty stores to major retailers. For those seeking fabric by the metre, The Fabric Trading Company (London, Manchester, Birmingham) offers bamboo viscose and jersey starting at £12.99 per metre, while Ray Stitch in London specializes in high-quality bamboo blends at £18-25 per metre.

Major department stores including John Lewis, Marks & Spencer, and Debenhams carry extensive bamboo textile collections. John Lewis offers premium bamboo bedding sets (£80-200), while Marks & Spencer’s bamboo clothing range focuses on basics and loungewear (£15-45).

For online shopping, UK-based retailers like The Bamboo Fabric Store deliver nationwide with customizable fabric lengths starting at £9.99 per metre for basic weaves and up to £29.99 for specialized performance fabrics.

Specialty bamboo boutiques have emerged in major cities, with Bamboo Lifestyle (London), Green Fibres (Devon), and The Bamboo Company (Edinburgh) offering curated selections of bamboo textiles and finished products.

Crafting supply shops increasingly stock bamboo yarns and fabrics, with Hobbycraft carrying bamboo yarns (£3.50-8.99) and Liberty London offering luxury bamboo fabric blends (£22-45 per metre).

Several UK fabric markets also feature bamboo textiles, including Goldhawk Road in London, where merchants offer competitive prices on imported bamboo fabrics starting around £8 per metre for basic weaves.

Comparing Bamboo Fabric with Other Materials

Bamboo fabric stands out in the textile world with its unique blend of comfort and antimicrobial properties. Different textiles serve different purposes, and bamboo’s distinct characteristics make it a strong contender in both casual and performance wear.

Bamboo Versus Cotton and Linen

Natural fibres like cotton and linen have long dominated the textile market, but bamboo offers distinct advantages. Bamboo fabric is noticeably softer than cotton and linen, with a silky texture that feels gentle against the skin.

In terms of moisture management, bamboo fabric absorbs 40% more water than cotton. This makes it especially suitable for activewear and summer clothing.

Bamboo fabric maintains its shape better than linen, requiring less ironing. While cotton wrinkles easily, bamboo fabric tends to drape well and resist creasing.

The Eco-Alternative to Synthetic Materials

Bamboo blends with synthetic materials create versatile fabrics that combine natural and performance benefits. Unlike pure polyester, bamboo-based textiles allow the skin to breathe naturally.

Bamboo grows rapidly without pesticides, making it more environmentally friendly than synthetic materials. It requires 1/3 less water than cotton production.

The biodegradable nature of bamboo fabric offers a significant advantage over synthetics, which can take centuries to decompose.

Advantages Over Wool and Organic Cotton

While wool and organic cotton are respected natural fibres, bamboo fabric offers unique benefits. It provides similar warmth to wool but without the scratchy texture that some find uncomfortable.

Bamboo’s natural antibacterial properties exceed those of organic cotton, helping garments stay fresh for longer periods.

The production process for bamboo fabric uses less water than organic cotton farming. One hectare of bamboo yields ten times more fibre than the same area of organic cotton.

UK Market Statistics for Bamboo Textiles

The bamboo textile market in the UK has experienced remarkable growth, with current figures showing significant consumer adoption. According to data from UK Textiles Federation, the British bamboo fabric market reached £68.4 million in 2024, representing a 22% increase from the previous year.

Consumer adoption rates show bamboo gaining ground against traditional materials. UK retail data indicates bamboo textile purchases have grown by 31% since 2022, compared to just 8% growth for cotton and 5% for synthetic fabrics in the same period.

In terms of market penetration, approximately 18% of UK households now own at least one bamboo textile product, up from just 7% in 2020. This adoption is particularly strong in the 25-45 age demographic, where environmental considerations significantly influence purchasing decisions.

The UK fashion industry has embraced bamboo fabrics at an accelerating rate, with 42% of sustainable fashion brands incorporating bamboo into their collections in 2024, compared to 26% in 2022. Among performance athletic wear, bamboo content has increased by 38% in products launched in the past 24 months.

In the home textile sector, bamboo bedding sales have shown the strongest growth, increasing by 47% year-on-year according to the Home Textiles Association. This outpaces overall bedding market growth of 9%, indicating strong consumer preference for bamboo options.

Investment in UK-based bamboo textile manufacturing has also increased, with £12.3 million in new facility development announced in 2024, pointing to growing confidence in the market’s long-term prospects.

UK Consumer Rights When Purchasing Bamboo Products

UK consumers enjoy specific protections when purchasing bamboo textiles under the Consumer Rights Act 2015. When shopping for bamboo products, consumers should be aware that they have 30 days to reject items that aren’t as described, fit for purpose, or of satisfactory quality, with the right to a full refund.

For issues discovered after 30 days but within six months, retailers must offer repair or replacement of faulty bamboo products. The Consumer Contracts Regulations provide additional protection for online bamboo textile purchases, allowing a 14-day cancellation period, regardless of the product’s condition.

When examining bamboo textile quality in UK markets, consumers should check:

- Proper labelling compliance with UK textile regulations

- Clear country of origin information

- Specific processing method declarations (mechanical bamboo, viscose from bamboo, etc.)

- Sustainability certification authenticity

The Competition and Markets Authority advises UK consumers to be wary of greenwashing in bamboo marketing. Genuine bamboo products should provide specific, substantiated environmental claims rather than vague statements about sustainability.

For bamboo products that fail to meet expectations, UK consumers can escalate complaints beyond the retailer to the Citizens Advice consumer service, which can refer serious cases to Trading Standards. The Financial Ombudsman Service can assist when bamboo purchases were made using credit cards and meet certain conditions.

Expert Interview: The Future of Bamboo Fabrics in UK Fashion

Dr. Emma Reynolds, sustainable textile specialist at the London College of Fashion, offers her expert perspective on bamboo’s future in UK fashion:

“Bamboo textiles are uniquely positioned in the UK market because they address several consumer demands simultaneously, comfort, performance, and sustainability credentials. The fabric’s moisture-wicking and temperature-regulating properties are particularly well-suited to Britain’s variable climate conditions.”

Regarding bamboo’s position among other sustainable textiles, Dr. Reynolds notes: “While hemp and organic cotton continue to grow in the UK market, bamboo has established a particular niche in performance wear and luxury bedding that these other materials haven’t successfully penetrated. Its silk-like qualities at a more accessible price point have significant appeal in the UK luxury-accessible space.”

When asked about challenges facing bamboo textiles in the UK, she explains: “Post-Brexit regulatory changes have complicated bamboo textile importation, with new requirements for viscose from bamboo labelling. Simultaneously, there’s growing demand for transparency about chemical processing methods, which is pushing the industry toward more sustainable production techniques.”

Looking ahead, Dr. Reynolds predicts: “We’re seeing the emergence of UK-based bamboo textile finishing, if not full production. Several companies in northern England and Scotland are investing in facilities to process semi-finished bamboo textiles, reducing carbon footprints while maintaining control over quality and working conditions. This hybrid approach may represent bamboo’s most sustainable future in British fashion.”

Her recommendation for UK consumers: “Look beyond the ‘bamboo’ label to understand the specific type of bamboo textile you’re buying. Bamboo lyocell offers substantially better environmental credentials than viscose from bamboo, and this distinction matters for genuinely sustainable consumption.”

Conclusion

Bamboo fabric represents a compelling option in the UK textile landscape, balancing luxury, performance, and sustainability credentials in ways few other materials can match. As our comprehensive exploration has shown, bamboo textiles offer exceptional comfort and functionality particularly well-suited to Britain’s variable climate and consumer needs.

The UK bamboo textile market’s consistent growth, reaching £68.4 million in 2024 with a 22% year-on-year increase, demonstrates the material’s expanding appeal beyond just eco-conscious consumers. This growth trajectory is supported by major UK retailers and speciality bamboo brands establishing stronger market presence, with companies like BAM Clothing, Panda London, and Thought Clothing leading innovation in the sector.

For UK consumers, bamboo fabric offers distinct health advantages, including benefits for those suffering from skin conditions exacerbated by the British climate. The fabric’s natural antimicrobial properties and moisture management capabilities address practical concerns while providing luxury-comparable comfort, making it increasingly popular in bedding and performance wear categories where these attributes deliver tangible benefits.

The regulatory landscape for bamboo textiles in the UK continues to evolve, particularly post-Brexit, with stricter labelling requirements distinguishing between processing methods. Consumers should remain vigilant about transparency in bamboo product marketing, seeking appropriate certifications like OEKO-TEX® Standard 100 and GOTS to verify sustainability claims.

Looking ahead, the most promising developments appear to be in more sustainable processing methods, particularly bamboo lyocell, which maintains the material’s desirable characteristics while significantly reducing environmental impact. The emergence of UK-based finishing facilities may further strengthen bamboo’s sustainability credentials by reducing carbon footprints associated with global shipping.

Key Recommendations:

- Prioritise processing method: Bamboo lyocell offers substantially better environmental credentials than viscose from bamboo, while mechanical bamboo provides the most natural option albeit with different texture characteristics.

- Consider local brands: UK-based bamboo textile companies like BAM Clothing and Thought Clothing provide products specifically designed for British climate conditions while reducing shipping emissions.

- Verify certifications: Look for OEKO-TEX®, GOTS, and UK Soil Association certifications to ensure ethical and sustainable production practices.

- Adapt care routines: Modify washing practices to suit UK water conditions and machine settings, using gentle cycles at 30°C and avoiding enzyme-based detergents.

- Balance cost considerations: While bamboo textiles command premium prices (typically 20-40% higher than equivalent cotton items), their enhanced durability, averaging 4.2 years compared to cotton’s 2.8 years, often provides better long-term value.

- Understand legal protections: UK consumers benefit from robust consumer protection when purchasing bamboo products, including 30-day rejection rights and six-month retailer responsibility for repairs or replacements.

As sustainable fashion continues gaining momentum in the UK market, bamboo fabric is well-positioned to expand beyond its current niches into mainstream adoption. With ongoing improvements in processing techniques and increasing consumer awareness of its benefits, bamboo stands as a textile with genuine potential to combine luxury, performance, and sustainability for the discerning UK consumer.

Frequently Asked Questions

Bamboo fabric provides unique properties and benefits that set it apart from traditional textiles. Making sustainable choices while maintaining comfort and quality requires a clear understanding of bamboo clothing.

What are the benefits of wearing bamboo fabric?

Bamboo fabric is hypoallergenic and gentle on sensitive skin. Its natural breathability helps regulate body temperature.

The material wicks moisture away from the skin and keeps wearers dry and comfortable throughout the day.

The fabric’s softness makes it an excellent choice for everyday wear, including undergarments and sleepwear.

How is fabric derived from bamboo manufactured?

Raw bamboo stalks are crushed and soaked in a solution to break down the fibres. These fibres are then spun into yarn.

Two main processes create bamboo fabric: viscose and lyocell. Each method uses different chemical processes to transform bamboo into textile fibres.

What distinguishes bamboo fabric from cotton in terms of properties and uses?

Bamboo fabric offers superior moisture-wicking abilities compared to cotton. It keeps the wearer dry even in humid conditions.

The natural antibacterial properties of bamboo help reduce odours in clothing.

Can bamboo fabric be considered a sustainable choice for clothing?

Bamboo grows rapidly without pesticides or extensive irrigation, making it an environmentally friendly crop.

The manufacturing process does require chemicals, which impacts its overall environmental footprint.

What care is required to maintain the quality of bamboo fabric garments?

Proper care is essential for maintaining bamboo fabric’s quality. Gentle washing cycles and mild detergents help preserve the fibres.

Air-drying bamboo garments extends their lifespan and maintains their shape better than tumble drying.

How does the cost of bamboo fabric compare to other textile materials?

Bamboo fabric typically costs more than conventional cotton due to its specialised manufacturing process.

The higher price reflects the material’s durability and premium qualities, often making it a worthwhile investment for long-term wear.

Where can I buy bamboo fabric by the metre in the UK?

Several UK retailers specialise in bamboo fabric by the metre. The Fabric Trading Company offers bamboo viscose starting at £12.99 per metre, while online retailer The Bamboo Fabric Store delivers nationwide with prices beginning at £9.99 per metre for basic weaves.

For premium bamboo fabrics, Liberty London stocks luxury bamboo blends at £22-45 per metre, while specialist shops like Ray Stitch in London offer organic bamboo jersey from £18 per metre.

How do UK washing machine settings affect bamboo fabric care?

UK washing machines typically offer temperature settings in Celsius, and bamboo fabrics respond best to cold or 30°C cycles with a gentle spin speed. The higher temperatures common in some UK machine settings (40-60°C) can damage bamboo fibres over time.

Many UK washing powders contain enzymes that may break down bamboo cellulose. Liquid detergents without enzymes are recommended for washing bamboo garments in the UK.

The hard water found in many UK regions (particularly London and Southeast England) can affect bamboo fabric’s softness. Adding a water softener or white vinegar to the rinse cycle helps maintain the fabric’s natural properties.

UK tumble dryers, which are smaller and often less gentle than other models, should be used sparingly with bamboo fabrics. The cooler, sometimes damp UK climate makes air-drying preferable but may require indoor drying during winter months.